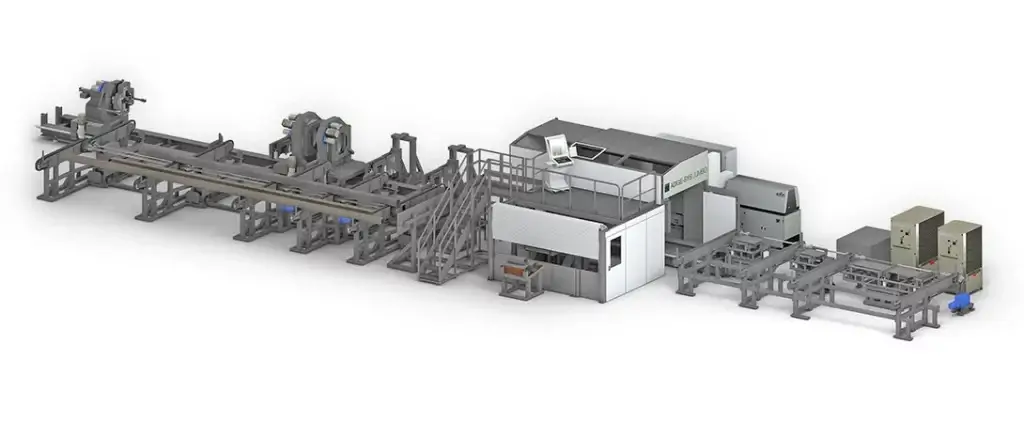

JUMBO-LT24-12500 AUTOMATA 3D TUBE AND PROFILE PROCESSING TUBE LASER CUTTER

Perfect laser cutting solutions for large metal structures

Find out more about the extraordinary capabilities of JUMBO-LT24 and discover how we can help your work!

EFFICIENT SOLUTIONS FOR CUTTING TUBES AND PROFILES

TUBE LASER CUTTING – PRECISE RESULTS

Our JUMBO-LT24- AUTOMATA machine represents the highest level of tube laser cutting, ensuring accurate and efficient cutting for every job.

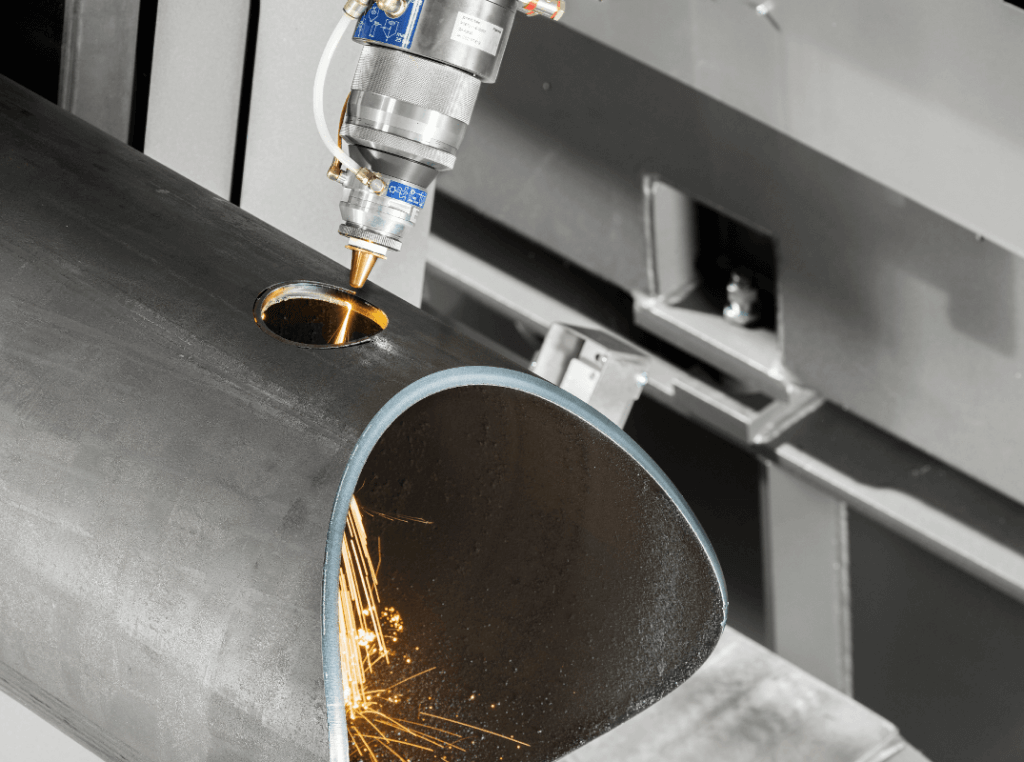

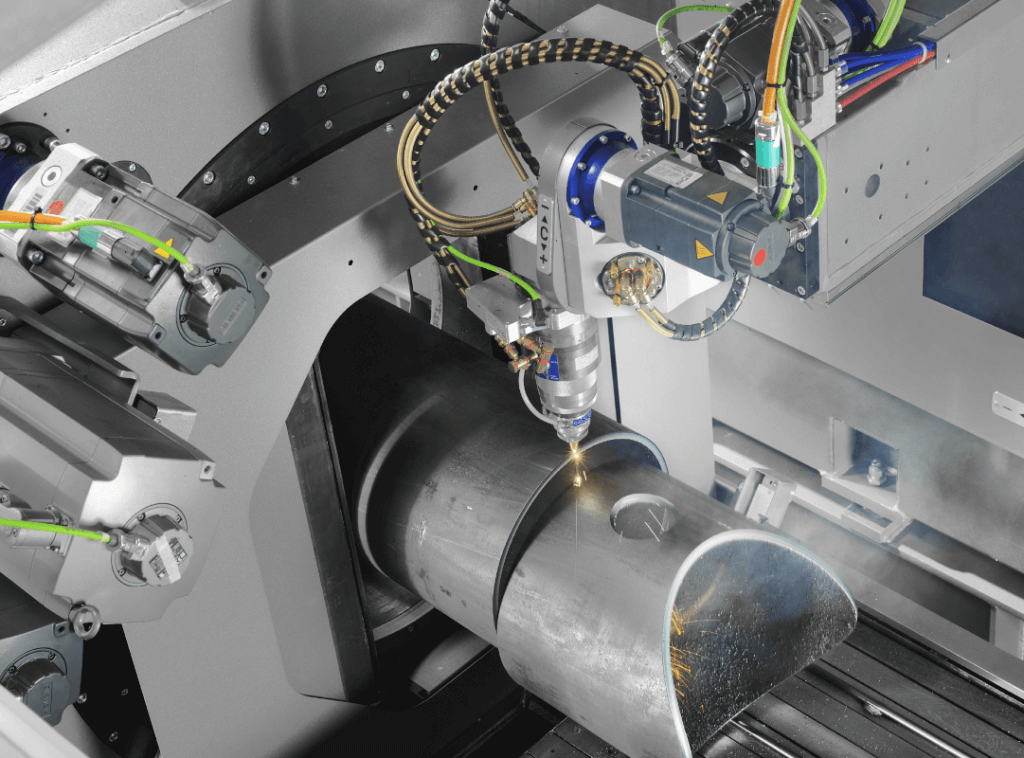

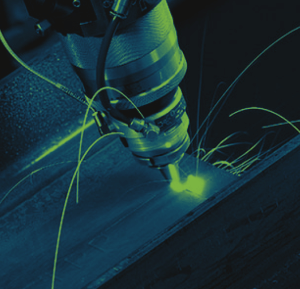

Tube laser cutting is a highly efficient technology that uses concentrated thermal energy to cut metal materials accurately and cleanly. Our JUMBO LT24 tube laser cutting machine is equipped with state-of-the-art technology and performs special processing operations perfectly.

The 3D cutter head can quickly and accurately cut profiles and tube components up to 12 metres in length and 55 to 610 mm in diameter. A single laser operation replaces cutting to size, deburring, punching, drilling and milling.

TUBE LASER CUTTING FEATURES – SPEED AND QUALITY

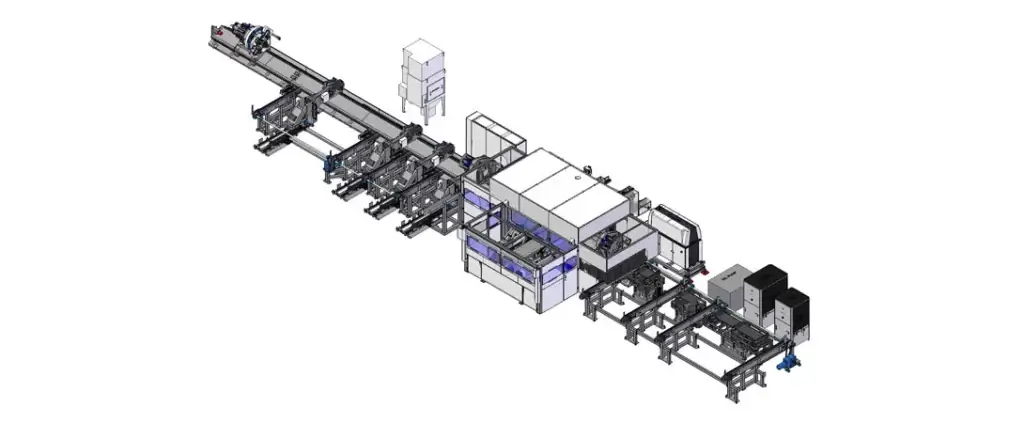

Tubes and profiles are processed with high technological and professional know-how. Our JUMBO-LT24-12500 AUTOMATA 3D tube and profile cutting machine boasts outstanding features such as high speed, automated operation and easy implementation of design patterns.

IN DIFFERENT SHAPES, SIZES AND MATERIALS

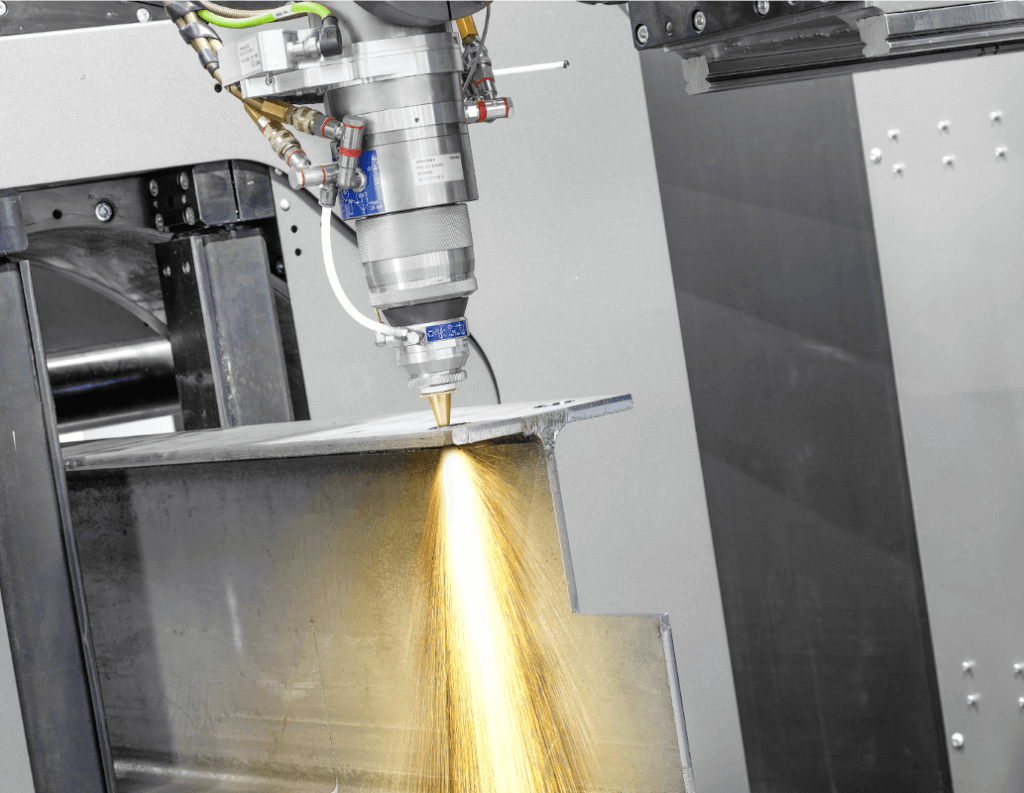

Benefits after the cut

We can easily perform bevel cutting of ends and holes, which is a particular advantage for parts to be welded. Processed edges require no post-processing and are ready for further operations immediately.

Effective cutting on difficult surfaces

We also effectively process dirty or rusty surfaces.

Fast processing

Reliable automatic settings can save significant time. We reduce the time per workpiece spent on repairs, maintenance and moving with conventional technology.

Cost reduction through material savings

By optimising the cuts, we minimise waste generated at the end of the tubes and get the most out of each profile.

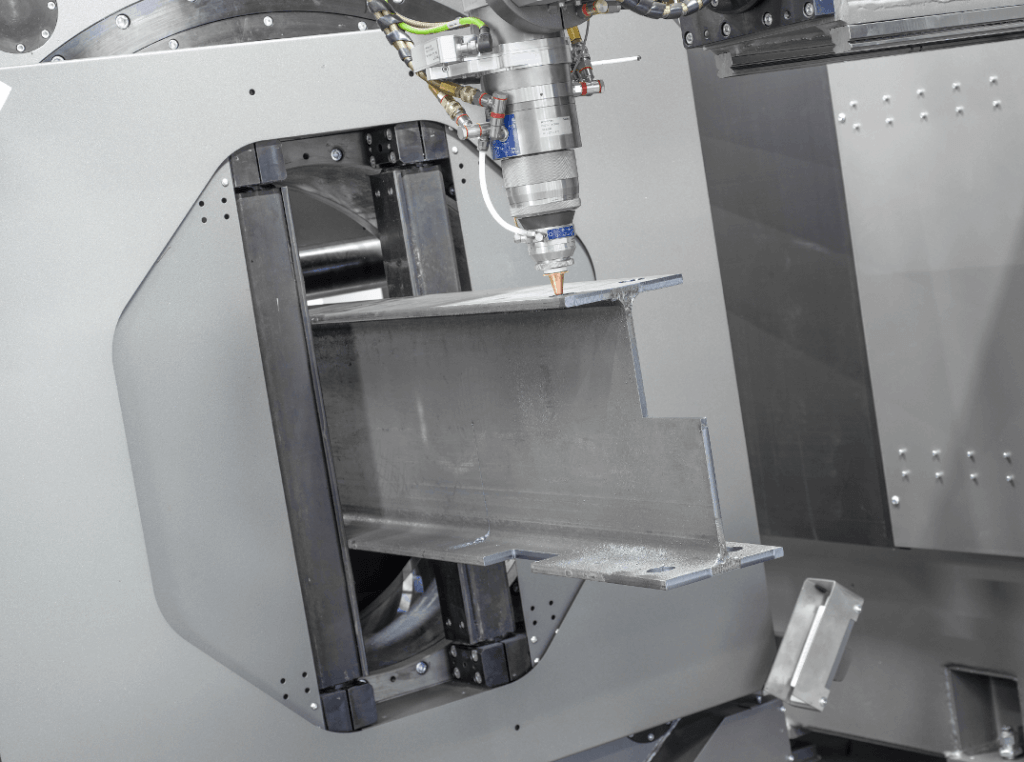

Easy processing of heavy profiles

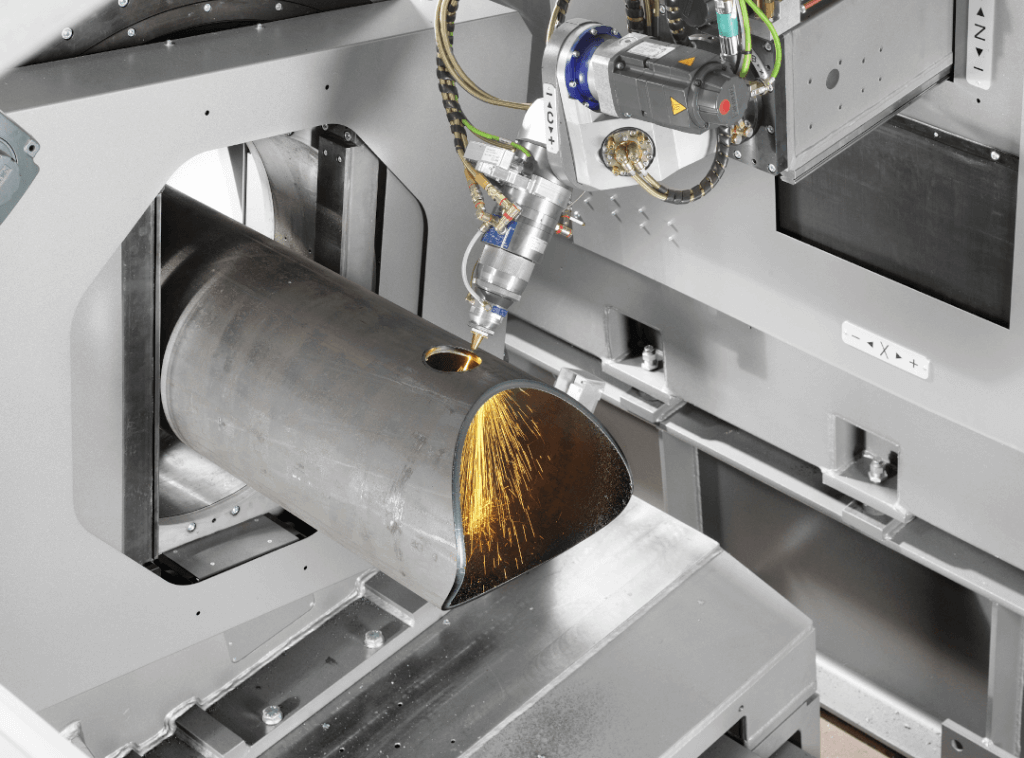

Tubes and profiles are clamped firmly with three spindles before processing, so that even the most demanding workpieces can be cut quickly and accurately. We minimise the risk of damaging profiles.

Precise implementation

With tube laser cutting, maximum precision is achieved in one step. Further operations can be carried out on the processed parts without the need for adjustment or rework. During the preliminary survey, we optimise the material to be processed, which is prepared using 3D design software and integrated into the machine in no time. Perfect processing is carried out with the support of production management software.

Special and large size cutting

The perfect choice for those who don’t want any compromise.

The 3D cutting head tube laser allows the processing of profiles and tube components up to 610 mm in diameter and 12 m in length.

Choose security

The functionality and aesthetics of tubes and profiles are not compromised by tube laser cutting. There is no need to use traditional processing markings (such as spike markings or smears). We have all EU required certifications, making the tube laser a Class 1 laser system designed to the highest safety and quality standards. The processed workpiece is constantly monitored.

Choose us for the highest quality, speed and flexibility in tube laser cutting.

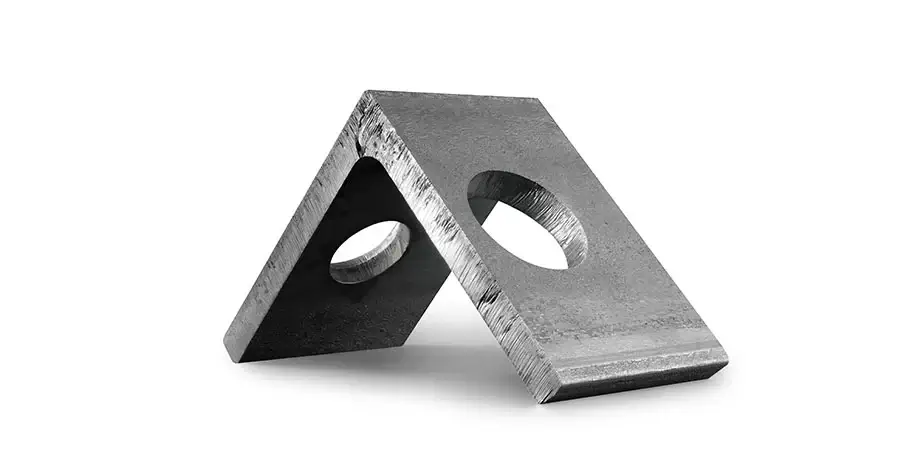

Standard or special cuttable shapes and materials

Whether your profile is round, square or rectangular, open or special, our cutting solutions create reliable and stable products for the long term.

Both open-ended and closed-ended individual pieces are easily processed.

Cuttable materials

We achieve excellent processing results in carbon and stainless steel and AL6060 aluminium alloy materials. Our tools are particularly suitable for precision cutting of these metal materials.

Champion of tube and profile processing

Tube laser cutting is a technology requiring high precision and innovation, where the energy of laser light is used to cut metals. Our JUMBO LT24-12500 AUTOMATA 3D tube and profile cutting machine uses the most advanced laser technology, guaranteeing high quality and efficient cutting process.