Grants

Introduction of production innovation and production management system at Vass Acélcsarnok Kft.

GINOP_PLUSZ-1.1.2-21-2021-00010

Name of beneficiary: Vass Acélcsarnok Korlátolt Felelősségű Társaság

- Object and purpose of the development: Introduction of production innovation and production management system at Vass Acélcsarnok Kft.

- The amount of the conditionally non-repayable European Union support is: 406,500,000 HUF.

- Detailed description of the project content:

Vass Acélcsarnok Kft. was founded in 2001 and since then it has been continuously developing its activities both in terms of technology and human resources. Within the framework of the project, the company is developing the activity 2511 ’08 Production of metal structures. The development to be implemented is aimed at linking the company to the digital and automated technological development related to Industry 4.0. By developing their production technology, they will be able to increase their production significantly (from 160 t to 600 t/month), which will enable them to strengthen their presence on the external markets, in addition to the steadily growing volume of domestic sales.

Place of implementation: H-8154 Polgárdi, topographical lot number 06.

The development consists of the following parts:

- Jumbo-LT24-12500 Automata 3D tube and profile processing laser production cell with feeding and unloading system

- WPS-3006 3D high-precision sheet metal processing production cell

- Flexi-30 VSD-OMD Ventilation system with high performance refrigerated dryer single compressor

- Making a machine base floor and pit

- Electricity extension (3 x 800 Amps)

- Installation of a heat pumped sanitary hot water storage

- Participation in a foreign exhibition

- Information Technology Development – Production Management System (Cloudberry MES – EXPERT)

The aim of the project is to develop technology, production innovation and services to expand the business in foreign markets.

As a result of the development, the acquisition of high-value equipment will simplify the company’s workflow, and the freed-up capacity can be reallocated to further meet increasing customer volumes and demands.

- Project ID number: GINOP_PLUSZ-1.1.2-21-2021-00010

- Project completion date: 21.06.2024.

Introduction of production innovation and production management system

Jumbo-LT24-12500 Automata 3D tube and profile laser

- One of the most advanced tube lasers currently available

- It allows cutting tubes and profiles up to 25 mm thickness, 55 to 610 mm in diameter and 12 metres long. It is also suitable for drilling, milling and threading operations.

- No such machine exists in Central and Eastern Europe

Jumbo-LT24-12500 Automata 3D tube and profile laser

The tube laser is 37 m long, 12 m wide and 4 m high

Gallery

I. Press release

Vass Acélcsarnok Kft. organised and hosted a press conference. The press conference was held on 20 June 2022 at the Hiemer House (H-8000 Székesfehérvár, Oskola u. 2-4), starting at 10:00.

II. Opening Press Event

At the opening press event, the owner János Vass welcomed the invited guests, followed by a detailed briefing on the project and the phases of the investment by Ágnes Vass, Head of Organisational Development.

Fotó: Juhász Bence

The ventilation system has arrived

On 25-26 February 2023, the Flexi-30 VSD-OMD Ventilation System with high performance refrigerated dryer single compressor, micro dust filter arrived at Vass Acélcsarnok Kft. The equipment is manufactured by Tolpec GmbH, SCC Compressor Technik.

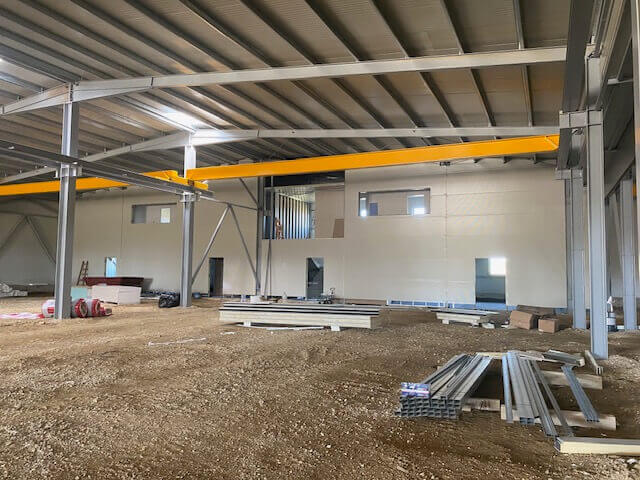

Construction of the new site is underway

The development of the Vass Acélcsarnok Kft. site is on schedule.

We have moved into our new premises

In February 2024, both production and the entire office administration moved into our new 4 unit, almost 8000 m2 site, designed and developed in-house. The modern facility meets all our needs to continue to provide our customers with high quality products and services. The new hall is not just a building for us; it is a symbol of our commitment to our profession and our precision.

Our new address is Polgárdi-Bálintmajor

Our plasma cutting machine has been put into operation

The WPS-3006 3D high-precision sheet processing production cell has been commissioned at the Polgárdi site of Vass Acélcsarnok Kft. Our 3D cutting head plasma cutting machine efficiently cuts straight, angled or complex shapes. It is perfectly suited for cutting parts from sheet metal up to 3000 mm x 6000 mm. The plasma cutting machine can drill, mill or thread any sheet metal part with an accuracy of ± 0.05 mm. After a test run following commissioning, production can start.

Report: Vass Steel Hall Ltd. at the Intertool Trade Fair

We are pleased to announce that Vass Steel Hall Ltd. successfully participated in the Intertool trade fair held from May 23-26, 2024, Austria’s largest and most important manufacturing technology B2B event. This year was special as the fair was held jointly with the Schweissen International Welding Technology Fair, allowing visitors to explore a wide range of the latest industrial technologies at one location.

The fair took place in the picturesque city of Wels, where we were located at stand 0103 in hall 21. We proudly presented our latest developments in tube laser and plasma cutting technologies. These innovations enable professionals in metal processing to make their precision work even more efficient.

The equipment showcased at our booth provides exceptional accuracy and reliability, significantly contributing to increased productivity and reduced manufacturing costs. Visitors had the opportunity to experience the benefits of our machines firsthand through live demonstrations illustrating the application of our technologies in a real-world environment.

This event provided us with an opportunity to meet with existing and potential business partners, discuss our business strategies, and further strengthen our position in the European and international markets. Our participation in the Intertool trade fair reaffirmed our commitment to innovation and quality while offering us insights into future manufacturing technology trends.

Thank you to everyone who visited our booth and participated in our demonstrations. We look forward to welcoming you at our next meeting!