SUBCONTRACTING THE PROCESSING OF LARGE DIAMETER AND LARGE SIZE METAL STRUCTURES

Tube laser cutting and plasma cutting solutions for tubes and profiles

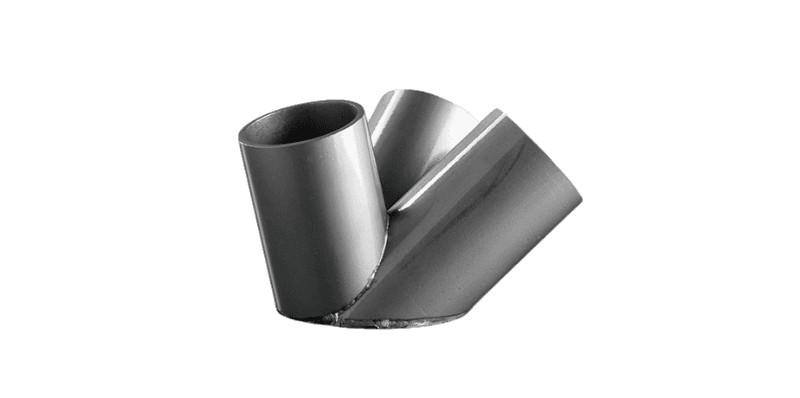

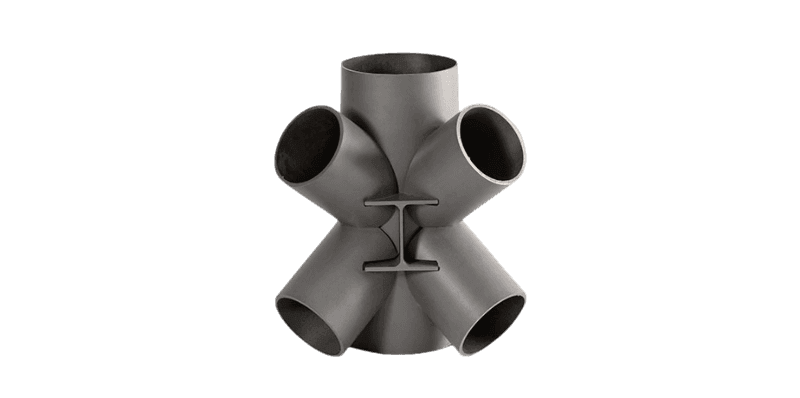

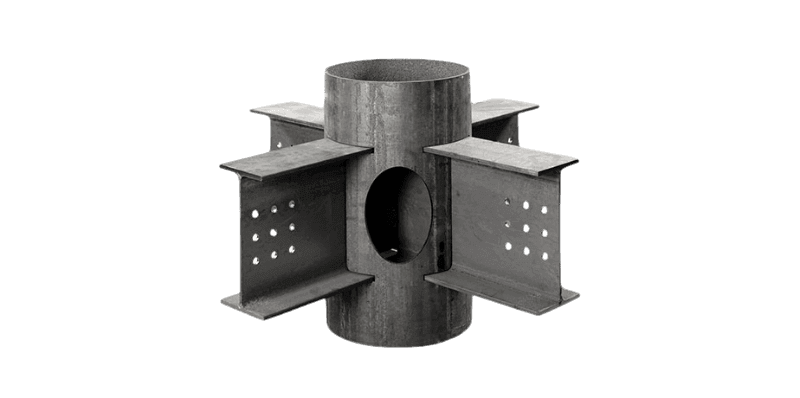

With 3D laser cutting, we eliminate the problems of joining finished structures, with holes and threads fitting together perfectly. Our system guarantees accurate production with minimum tolerances.

PRECISION laser CUTTING OF METAL TUBES AND BEAMS

IN DIFFERENT SHAPES, SIZES AND MATERIALS

Subcontracting the processing of large diameter and large size metal structures

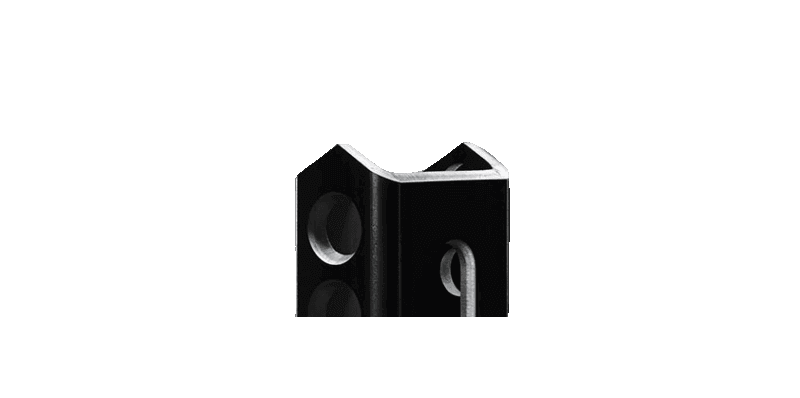

We specialise in the precision laser cutting of metal tubes and beams of different shapes, sizes and materials. We can also process difficult to move or bulky parts with pinpoint accuracy: we can carry out professional tube laser and plasma cutting of profiles up to 12 m long and 610 mm in diameter.

We are Vass Laser

AL6060 ALUMINIUM

WITH MAX. 6 MM

WALL THICKNESS

CARBON AND STAINLESS STEEL

CUTTING OF CIRCULAR CROSS-SECTIONS WITH COMPLEX GEOMETRIES

WE ALSO GUARANTEE ACCURATE CUTTING FOR SECTIONAL STEEL

Precise and efficient tube laser cutting

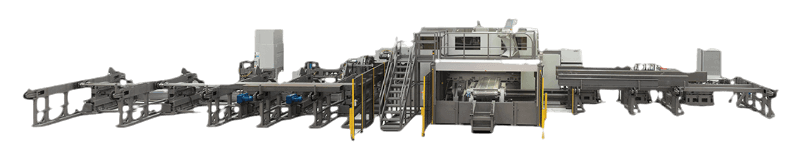

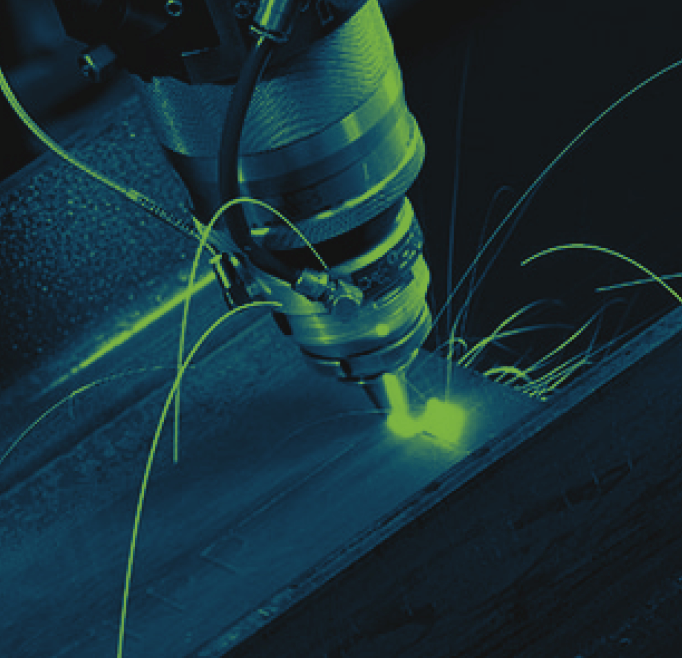

We specialise in precise and efficient tube laser cutting of metal beams and tubes. With our innovative tools and highly skilled professionals, we provide solutions that meet our customers’ needs with high quality and accurate dimensions. Our state-of-the-art tube laser cutting machine provides high accuracy and fast cutting speed, allowing complex shapes and sizes to be easily achieved.

Precise and efficient plasma cutting

Plasma cutting is a thermal cutting and parting process. Plasma cutting is very similar to the process of material separation by flame cutting. Our state-of-the-art plasma cutting machine provides high accuracy and fast cutting speed, allowing complex shapes and sizes to be easily achieved.

IN DIFFERENT SHAPES, SIZES AND MATERIALS

High precision and accuracy:

Our tube laser cutting technology enables precision to tenths of a millimetre, ensuring high-quality cuts and accurate dimensions.

Fast and efficient production:

Our modern tube laser cutting machine offers fast and efficient production, saving time and money for our customers.

Implementation of complex forms:

Tube laser cutting also makes it easy to create complex geometric shapes and patterns, giving us the flexibility to adapt to your specific needs.

Automation and accurate repeatability:

Our automated tube laser cutting systems ensure accurate repeatability, which is especially important for mass production and larger projects.

Material efficiency:

Tube laser cutting minimises waste and optimises material use, offering an environmentally friendly and cost-effective solution.

Choose us for the highest quality, speed and flexibility in tube laser cutting.

Our Jumbo-LT24 Tube and profile laser cutting machine