SUCCESS IS IN THE DETAILS.

We are proud of the fact that since our company was founded nearly 4 decades ago, we have gained complex experience in the production of steel structures, and we have made innovative investments. Our main profile is the production of light-weight structure steel halls, precise tube laser cutting and processing of metal beams and tubes. Our professional team is dedicated to providing creative, efficient solutions of the highest quality.

INTRODUCING VASS LASER

WE HAVE A MANUFACTURER’S SOLUTION FOR EVERY SUB-TASK

We have state-of-the-art equipment in our 7400 m2 manufacturing facility in Polgárdi: CNC controlled edge bending machines, plasma cutting machine, beam production line, band sawing machines, CO welding machines, grain and paint spraying equipment. We also have a separate painting plant on our premises. We currently employ nearly 70 people.

IN DIFFERENT SHAPES, SIZES AND MATERIALS

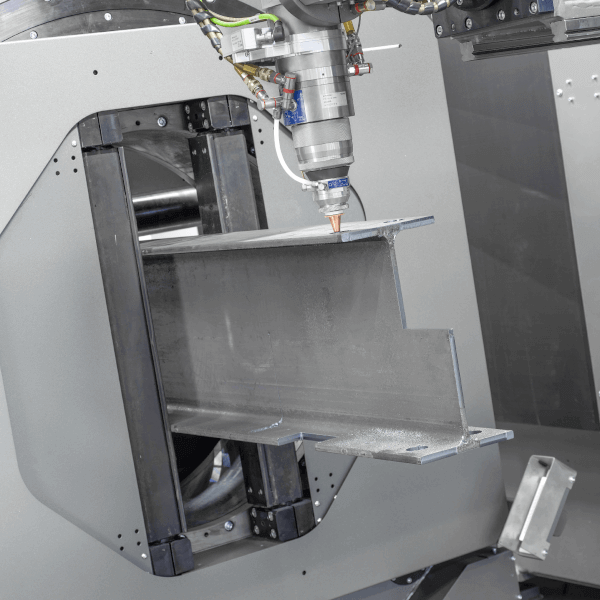

High precision and accuracy:

Our tube laser cutting technology enables precision to tenths of a millimetre, ensuring high-quality cuts and accurate dimensions.

Fast and efficient production:

Our modern tube laser cutting machine offers fast and efficient production, saving time and money for our customers.

Implementation of complex forms:

Tube laser cutting also makes it easy to create complex geometric shapes and patterns, giving us the flexibility to adapt to your specific needs.

Automation and accurate repeatability:

Our automated tube laser cutting systems ensure accurate repeatability, which is especially important for mass production and larger projects.

Material efficiency:

Tube laser cutting minimises waste and optimises material use, offering an environmentally friendly and cost-effective solution.

Choose us for the highest quality, speed and flexibility in tube laser cutting.

Said about us

Customer satisfaction is important to us. We are happy to share the recommendations and feedback we receive from them.

Our commitment and determination ensure that we excel in our industry and are trusted partners to our customers.

Come and see us!

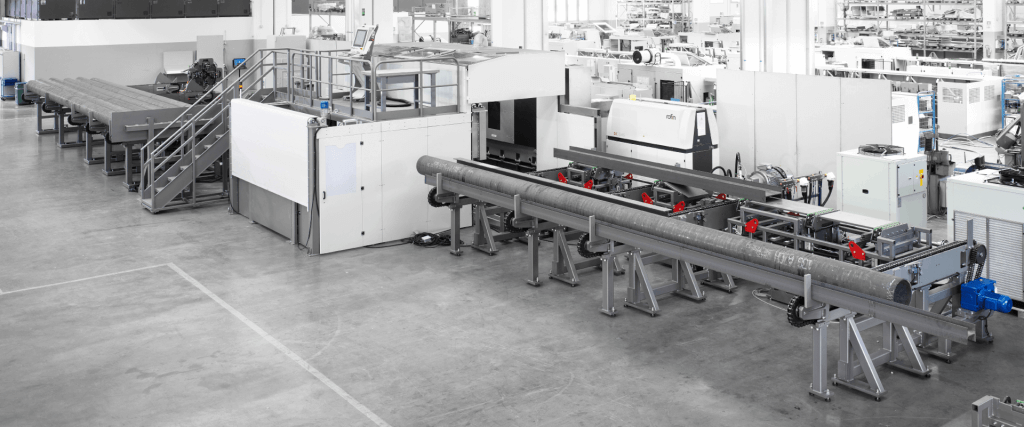

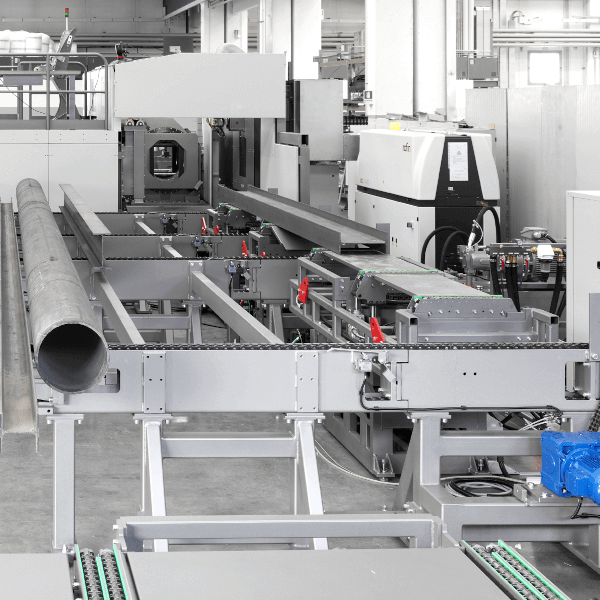

In 2023, we purchased a Jumbo LT-24 type tube and profile tube laser cutting machine under the Hungarian Multi Program grant. With this investment, it is now possible to cut profiles and structures up to 12 m in length and 610 mm in diameter. The tube laser cutter is used for fast and precise cutting of large metal profiles under subcontracting.

Our production equipment includes a 3D sheet metal plasma cutting machine, which can cut out sheet metal parts from plates up to 3000 mm x 6000 mm.

Our beam production plant equipped with a bridge crane produces galvanised C and Z beams with holes in various lengths.

Sheet processing is performed with a CNC edge bending machine. We perform bending and modification of bent building cornices, frames, boxed gutters, individual elements.

Our staff have the expertise to ensure that every step from design to production is perfect. In a dynamic working environment, the spirit of innovation and continuous improvement permeates our daily activities.